Automated vs. Manually-Created CAD Models

Are software-generated CAD models better or worse than those created manually by engineers? What are the pros and cons of each development style?

In this post, we list the pros and cons of each type of model, and then share SnapEDA’s development process.

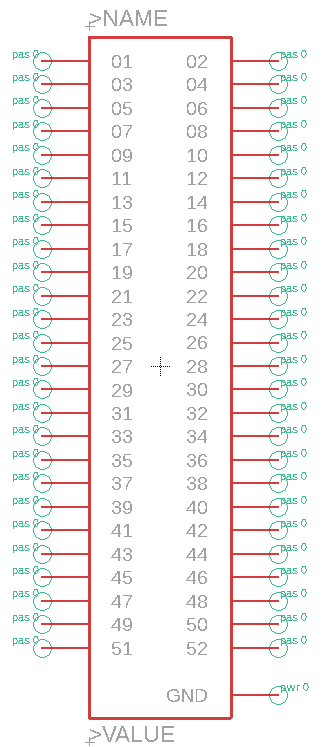

Manually-Created CAD Models

Manually created models are made individually based on a particular part number. When engineers are creating CAD models, they’ll typically work from checklists to ensure that the parts are created based on standards. At SnapEDA, we always use creation and verification checklists to ensure we don’t miss any critical aspects of the library, and to ensure proper interpretation of the datasheet by the initial creator of the part.

Pros:

– Manually-created CAD models are high-quality as long as they’re created based on standards, which are followed rigorously

– When models are manually-made, it is more likely they’ll follow datasheet recommendations if that is preferred, than an overarching standard like IPC.

Cons:

– Since model creation is manual, there’s a limit on how many can be produced well in a given unit of time

– Since it’s an error-prone process, verification is essential

– There’s a higher risk of inconsistency when producing models in the same family or series since the process is manual, and may have multiple engineers involved

Automated CAD Models

Software-generated CAD models, on the other hand, are produced to speed up the process of creation. This approach can be especially useful for parts that belong to the same series or family.

Pros:

– Hundreds of models (of the same packages) can be produced within minutes

– No need for manual library creation and verification, as long as the initial automation models (data and scripts) have been rigorously tested

– Ensures uniformity of models in the same family or series

Cons:

– Data extraction process need to be highly accurate and may require considerable time investment

– Incorrect data can produce multiple incorrect models

– Requires time, effort and expertise for script development and ample testing

At SnapEDA, we use both methods (often together) to create models. In either case, all our CAD models undergo a rigorous process to ensure quality.

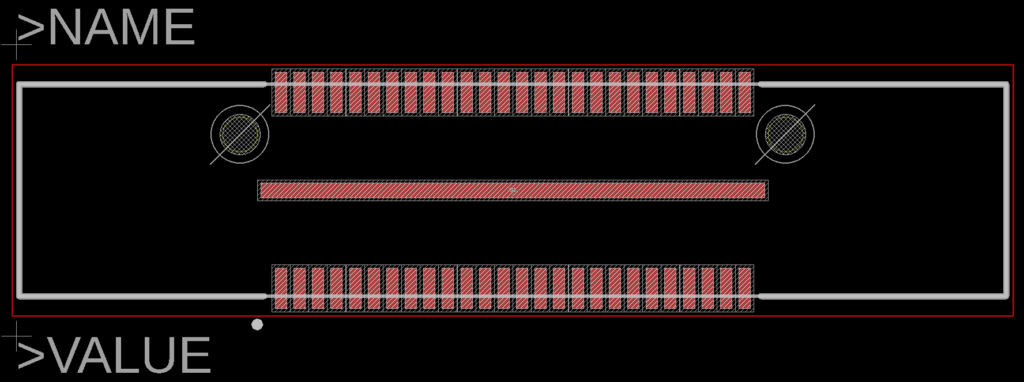

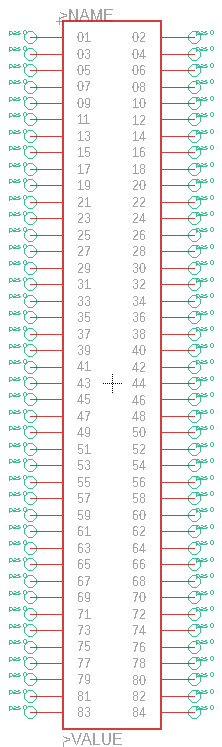

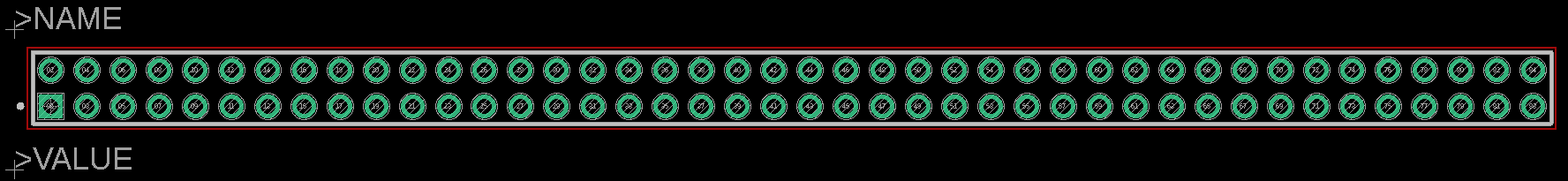

Our manually-created CAD models are made by our in-house engineers who follow a creation checklist based on IPC-7351B and IEEE standards. The created models will then undergo the verification process where our senior engineers monitor the quality of the libraries. A verification checklist is used for each model to catch any creation errors before they’re released to our community.

Automated CAD models, on the other hand, are generated through a script. The script is based on SnapEDA’s standards as well as data collection from manufacturers to ensure part accuracy. After the 1st batch of automated CAD models are produced, intensive quality checks are performed before launching the whole series.

So there you have it – both methods produce high quality models so long as the approaches follow standards and have been rigorously tested.

You can start searching for CAD models on SnapEDA here.